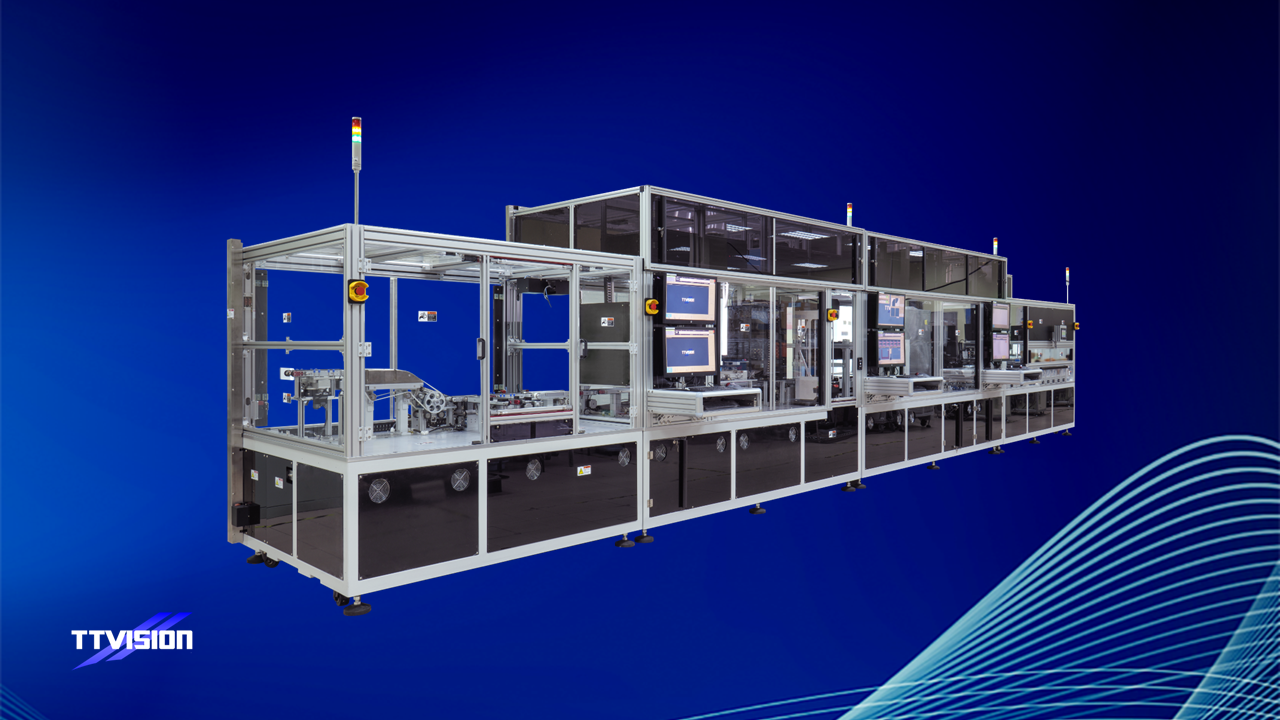

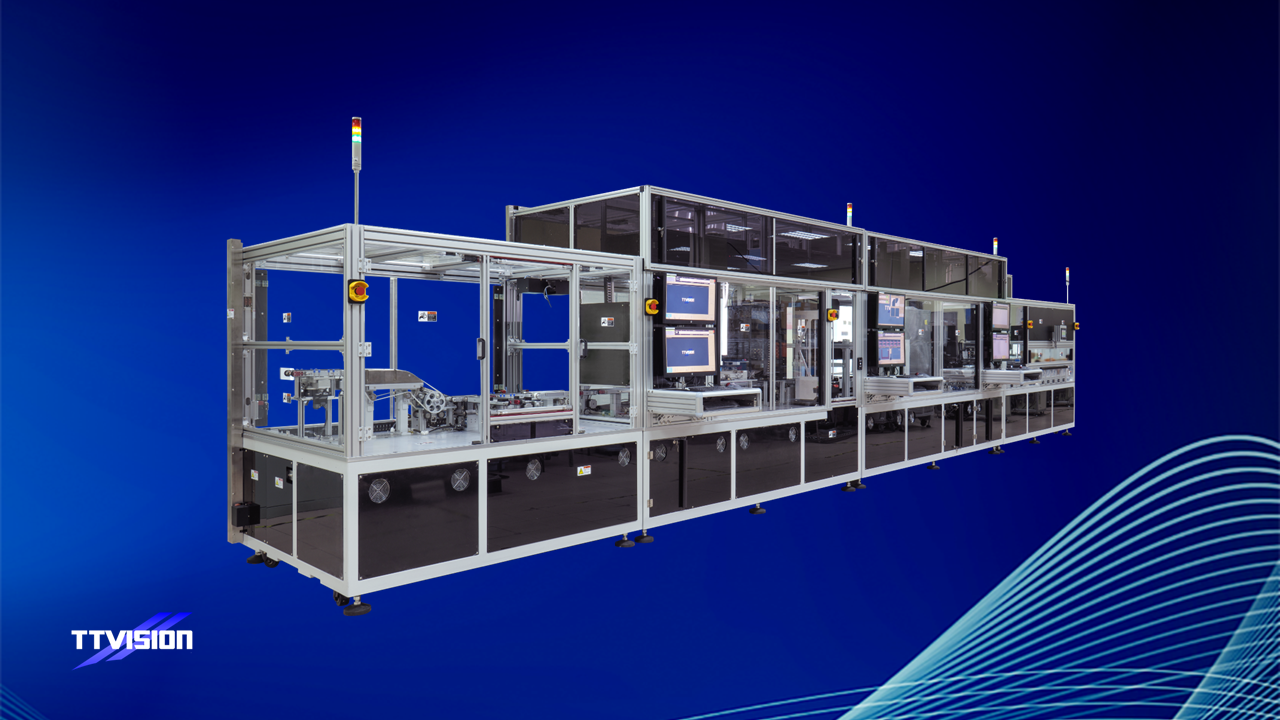

IBC Solar Cell Sorter

Product image

IBC Solar Cell Sorter

Description

The IBC Solar Cell Sorter stands as an advanced and versatile solution for the sorting and quality control of solar cells, offering a comprehensive array of features to meet the demands of modern solar manufacturing.

Features

- Full-Fledged Inspection, Testing, and Sorting:

- 3D Line Scan for Rear Side Inspection:

Utilize 3D line scan technology for detailed rear-side inspection. This method provides a comprehensive analysis, ensuring the identification of defects and irregularities on the rear surface of the solar cells. - Combination of Colour Line Scan for Front Side Inspection:

Achieve precision in front-side inspection with a combination of color line scan technologies. This dual approach enhances the accuracy of defect detection on the front surface of the solar cells. - PL for Micro-Crack and Solder Pads Defects Inspection:

Implement photoluminescence (PL) technology for the detection of micro-cracks and solder pad defects. This technique ensures a thorough examination, addressing critical aspects of solar cell quality. - Infrared Imaging for Hot-Spot Measurement:

Utilize infrared imaging for hot-spot measurement, enabling the identification of potential issues related to temperature differentials within the solar cells. This feature contributes to the overall safety and reliability of the solar modules. - Laser Profilometer for Metal Line Profile Measurement:

Employ a laser profilometer to measure the metal line profile of solar cells accurately. This technology ensures precise characterization of metal lines, contributing to the overall performance and efficiency of the solar cells. - Vision Aligner for Cell Positioning and Alignment for Probing:

Benefit from a vision aligner that facilitates precise cell positioning and alignment for probing. This feature ensures zero contact on the cell edges and higher probing accuracy in testing procedures, contributing to the reliability of the sorting process. - I-V Tester and Advanced Data Analysis:

Incorporate an I-V tester for accurate electrical characterization of solar cells. The advanced data analysis capabilities enhance the efficiency of the testing process, providing detailed insights into the performance of each cell. - Interleaf Paper Placement Before Cell Sorting:

Enhance the handling of solar cells with interleaf paper placement before sorting. This feature fulfils the need for protection and integrity of cells during the sorting process and packing. - Combination of Belt and Walking-Beam Conveyor:

Achieve high-speed and high-stability cell transportation with a combination of belt and walking-beam conveyor systems. This dual approach optimizes the transportation process, contributing to overall efficiency. - Throughput up to 2,400 Cells per Hour:

Experience impressive throughput with the capability to process up to 2,400 cells per hour. This high-speed operation ensures efficient sorting without compromising accuracy. - Capable of Handling Solar Cells Ranging from 5 Inches to 6 Inches:

The IBC Solar Cell Sorter is designed to handle solar cells within a range of 5 inches to 6 inches, providing versatility to accommodate various cell sizes.

.png)